Research into combustion systems and low-emission combustion processes

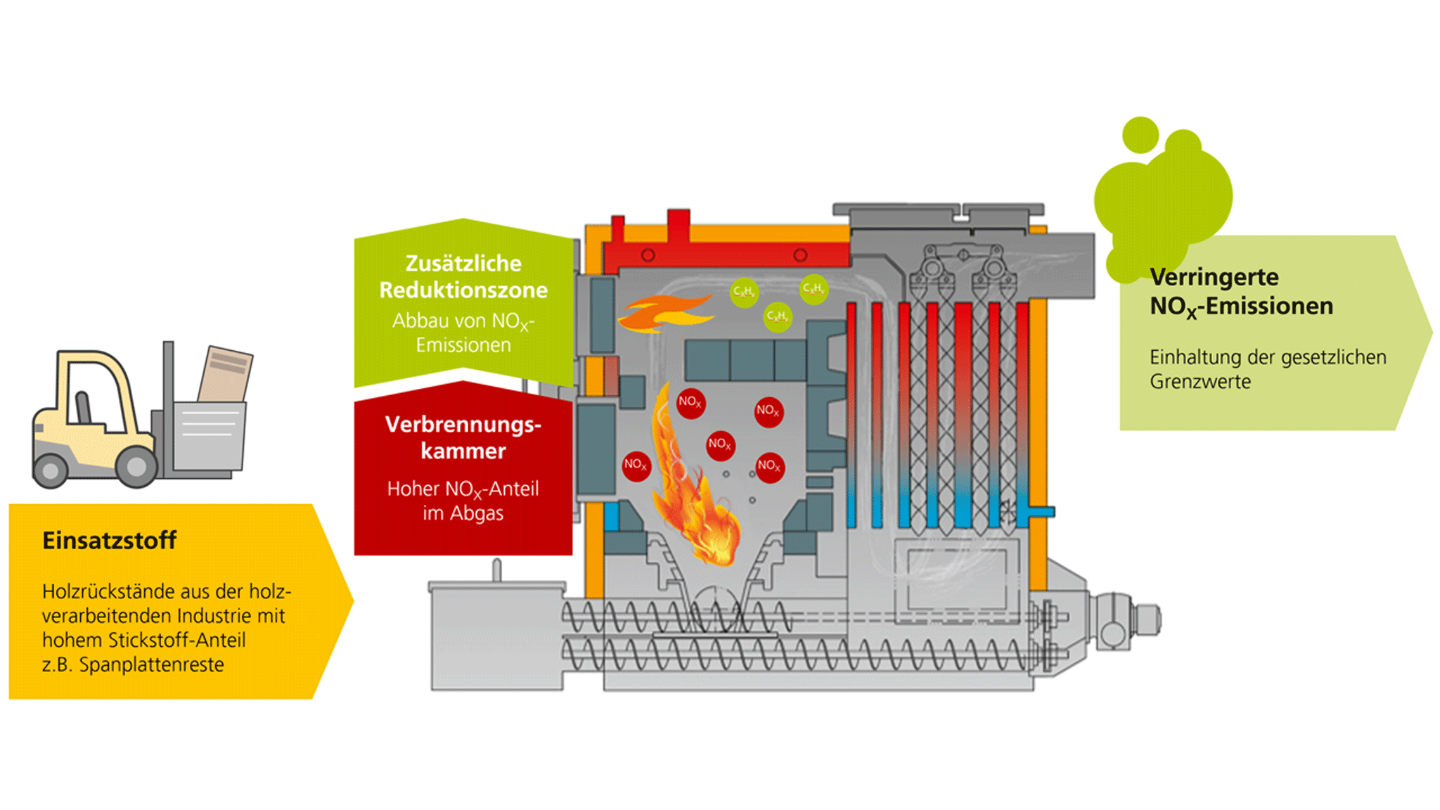

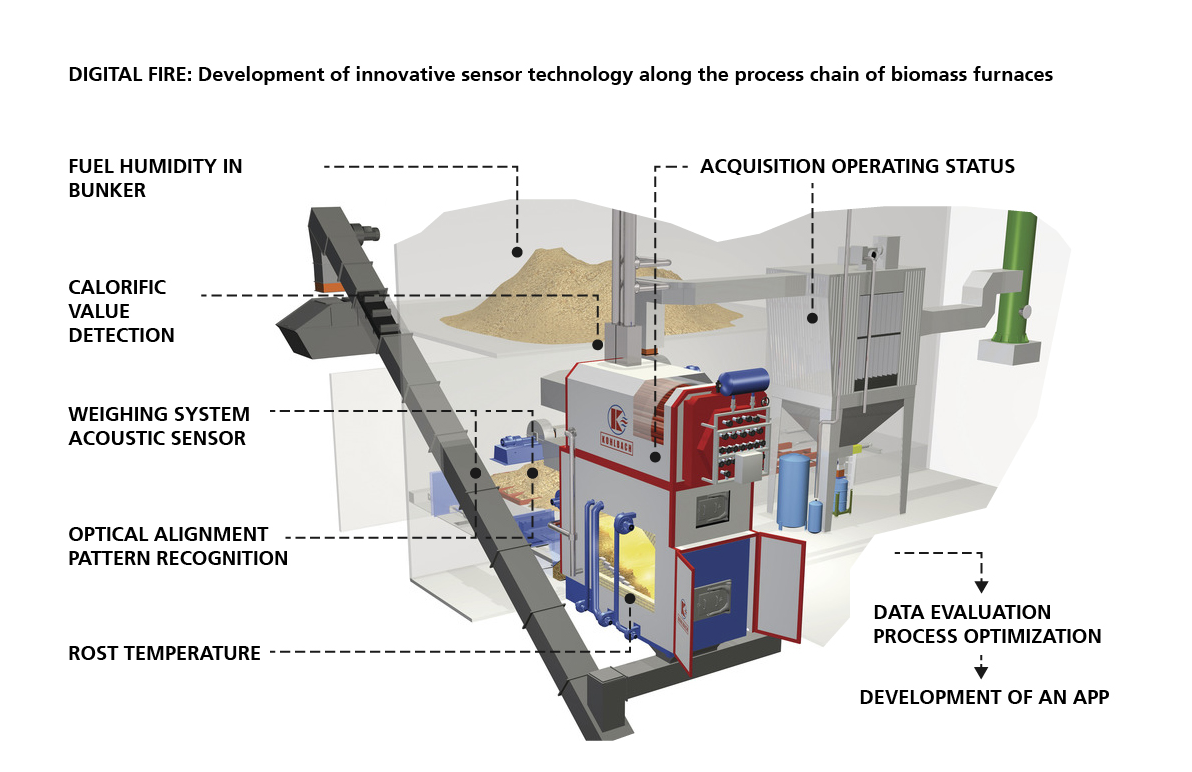

At the Sulzbach-Rosenberg branch of the Fraunhofer Institute UMSICHT, we develop, optimize and test combustion processes and combustion plants. One focus of our development and research work is on systems and processes for the optimal energy recovery of residual and waste materials, e.g. the combustion of biomass with a high nitrogen content.

The use of biogenic residues and waste to generate energy is an important component of sustainable energy production. In particular, the provision of industrial process heat poses a challenge.

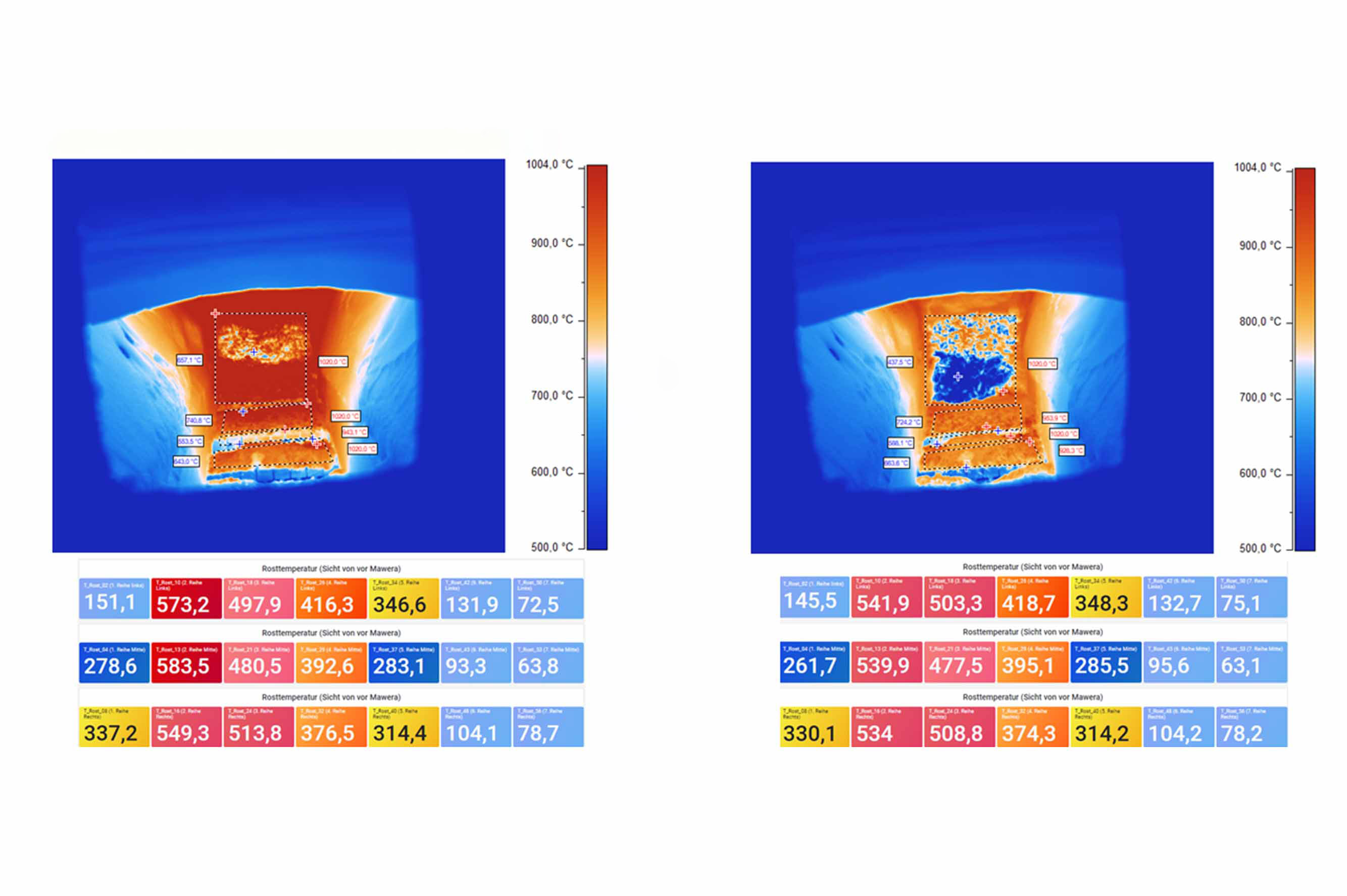

In the Clean Combustion and Process Heat department at the Sulzbach-Rosenberg branch of the Fraunhofer Institute UMSICHT, we develop, optimize and test combustion processes and combustion plants in order to make them suitable for the low-emission use of biomass solid fuels, production residues and various waste materials.

The aim is to develop combustion technologies that, on the one hand, meet stricter emission requirements (in particular NOx and particulate matter emissions) and, on the other hand, enable economical plant operation by also being able to use fuels of fluctuating or low quality.

The thrust of technology development for combustion technology at Fraunhofer UMSICHT is accordingly:

- Fuel-flexible plant operation in order to be able to use biogenic residues and heterogeneous waste in continuous operation.

- Highly effective emission reduction with primary and secondary measures to reduce pollutants and emissions as much as possible (near-zero emissions).

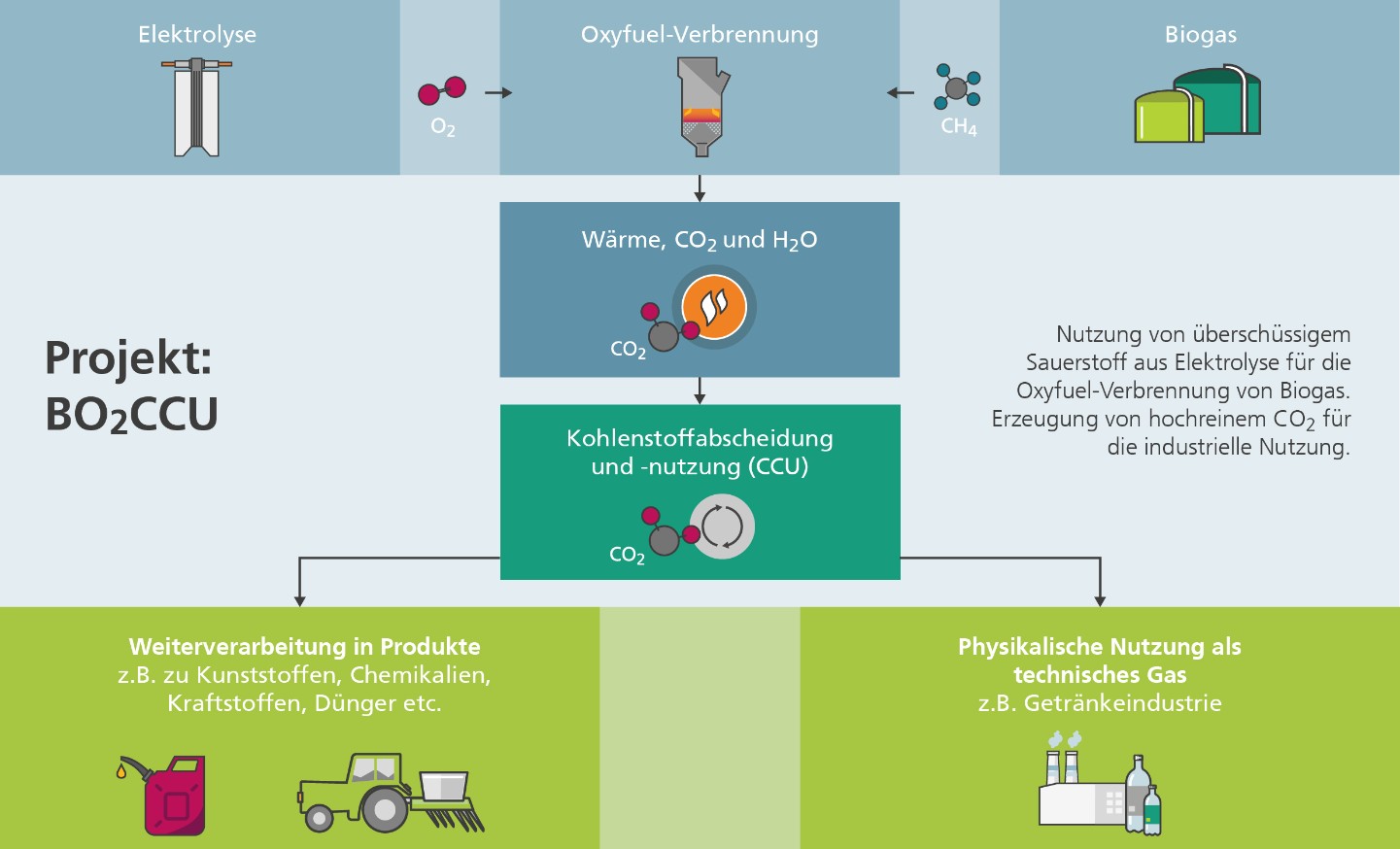

- The optimal integration of combustion systems into ideally CO2-negative process chains, in particular through the development of oxyfuel combustion processes and BECCU systems (Bionergy Carbon Capture and Utilization)

Our development work covers all performance ranges of combustion systems: from small combustion systems (single-room furnaces, boilers, stoves), automated biomass-powered (CHP) combustion systems in the medium output range / commercial segment to the optimization of power plant components in biomass cogeneration plants, RDF power plants or waste incineration plants.